Analytical Testing

Expect Precision and Insight with IntoCeramics

At IntoCeramics, we’re your partners in precision, guiding you through the intricate world of material analysis. Our analytical testing services offer a comprehensive suite of solutions designed to unravel the mysteries of your materials, ensuring quality, performance, and innovation.

The IntoCeramics Advantage

Unparalleled Expertise: Our team of seasoned engineers and ceramists brings a wealth of knowledge to every analysis. We’ll ensure you receive insightful results and relevant testing recommendations based on your materials and processes.

State-of-the-Art Equipment: From advanced particle analyzers to high-resolution imaging tools, we invest in cutting-edge technology to deliver accurate and detailed analyses — at extremely competitive prices.

Fast Turnaround: Time is of the essence. Our efficient processes ensure you get the information you need promptly, without compromising accuracy. We manage sample handling and submission to BMRC, including correlation of reporting for multiple samples.

Customized Solutions: We understand that every material is unique. That’s why our analytical testing services are tailored to address your specific needs, helping you make informed decisions.

IntoCeramics can assess the suitability of your materials for new products and processes and help you ask the right questions to find the best solution.

- How do I know what to test for?

- How do I determine which tests to run?

- Where can I find a testing facility to “do it all”?

- How do I interpret the test results to make the right decisions?

Get in Touch

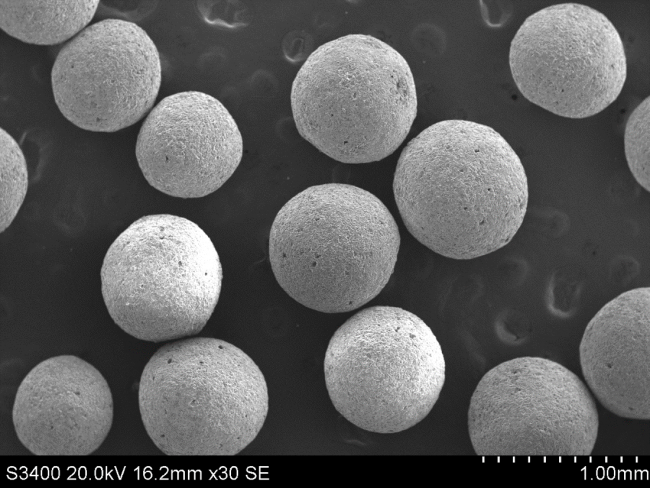

Shimadzu Laser Diffraction Particle Analyzer: Explore the Power of Precision

Experience a new dimension of accuracy with the Shimadzu Laser Diffraction Particle Analyzer. This cutting-edge instrument empowers us to delve deep into particle size distribution analysis, unlocking valuable information about your materials. Whether it’s ceramics, powders, or suspensions, this analyzer paints a precise picture of particle behavior, helping you optimize formulations, enhance product properties, and meet stringent industry standards.

The New Standard in Particle Size Measurement and Particle Size Distribution

Shimadzu’slaser diffraction technology is equipped with many new functions for evaluating changes (dispersion, dissolution, aggregation) in particle size distribution relative to the concentration or time. This instrument supports a particle concentration range from 0.1 ppm to 20% and can perform a series of measurements of 200 data points at 1-second minimum intervals.

Intoceramics Material Analytical Services

At IntoCeramics, our analytical testing services are designed to empower you with comprehensive insights into your materials’ behavior and properties. Whether you require a straightforward presentation of results or an in-depth written report, we cater to your needs, ensuring clarity and understanding at every step of the way.

We don’t just analyze; we understand. With an eye for detail and 50+ years of experience, we conduct suitability analyses that delve deep into the nuances of your materials. Our seasoned professionals provide invaluable perspectives that can shape your material strategies and drive your innovations forward.

INTOCERAMICS MATERIAL ANALYTICAL SERVICES |

|

Thermal Analysis |

Price |

Dilatometry (Air) |

$165.00 |

Dilatometry (Cryogenic) |

$365.00 |

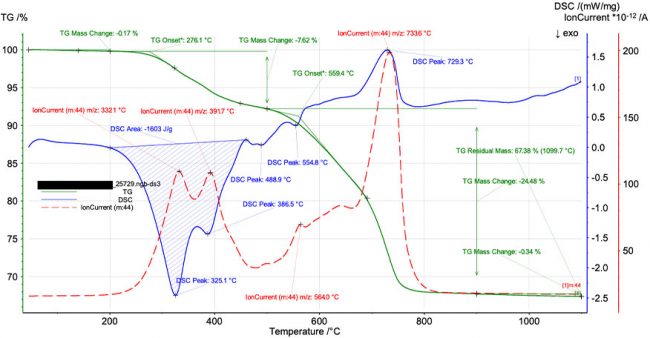

Simultaneous Thermal/Evolved Gas Analysis (TG/DSC/EGA |

$330.00 |

Simultaneous Thermal Analysis (TGA/EGA or TGA/DSC) |

$265.00 |

Chemical Analysis |

|

Loss on Ignition (LOI) |

$60.00 |

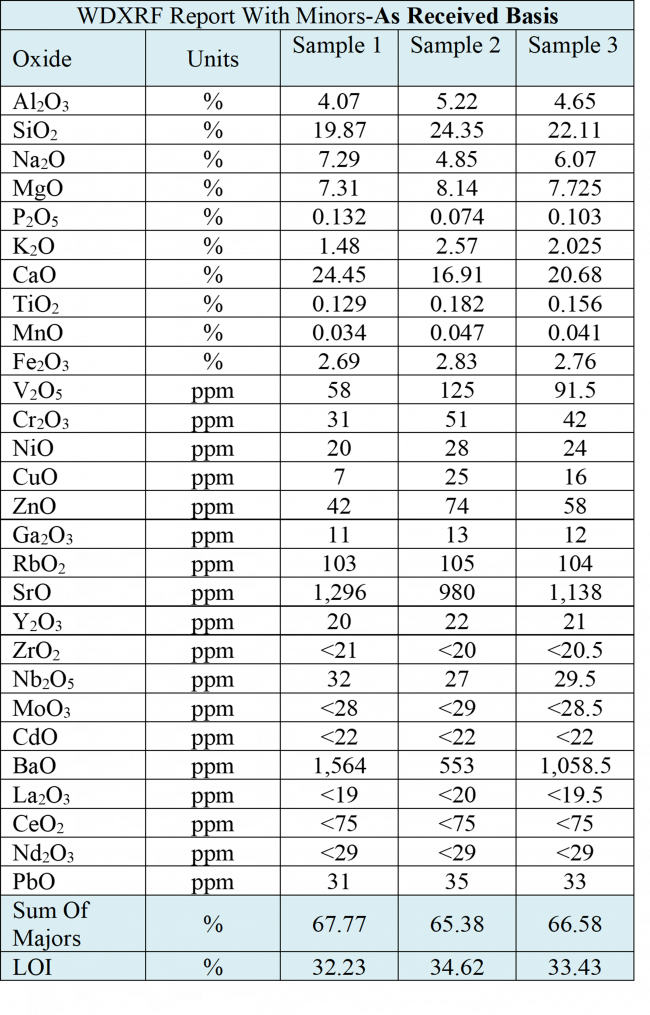

Semi-Quantitative XRF (X-Ray Fluorescence) |

$135.00 |

Quantitative XRF (X-ray Fluorescence Spectrometer) – Fusion, requires LOI |

$145.00 |

Inductively Coupled Plasma Spectroscopy (Leaching) |

Inquire |

Inductively Coupled Plasma Spectroscopy with Acid Digestion |

Inquire |

Soluble Salts Test (Cations/Anions) |

$200.00 |

Toxicity Characteristic Leaching Procedure (TCLP) |

Inquire |

Mineralogy |

|

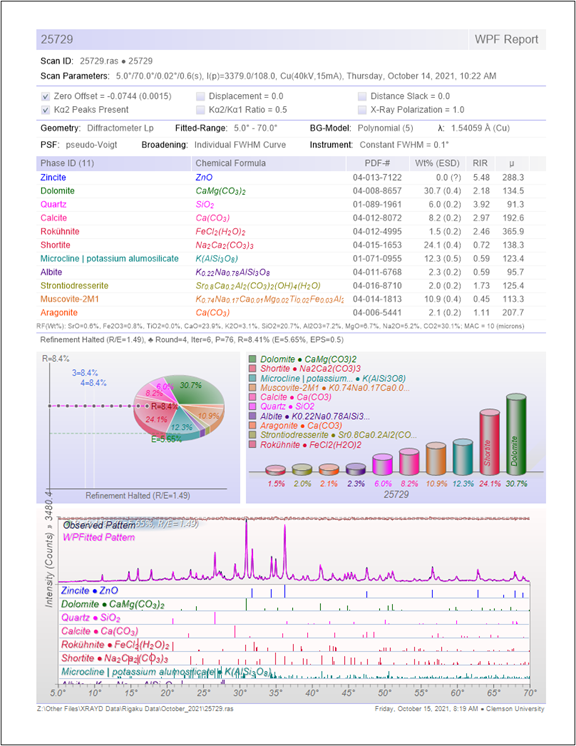

Semi-Quantitative X-Ray Diffraction, Phase Quantification (XRF/LOI Required) |

$160.00 |

Crystalline Silica (X-ray Diffraction) |

$200.00 |

Total Sulfur and Carbon (LECO) |

$110.00 |

Pyrite, Sulfate & Inorganic Carbon Determination (E1915) |

$215.00 |

Environmental |

|

Hydrogen Fluoride and Hydrogen Chloride Analysis by Pyrohydrolisis Method |

$220.00 |

Mass Balance ( Fluorides & Chlorides) |

$435.00 |

Mass Balance for Sulfur & Carbon |

$210.00 |

Mercury Mass Balance |

$145.00 |

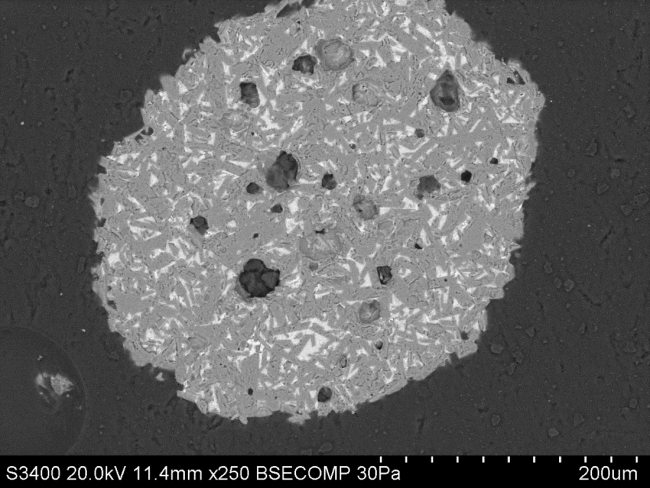

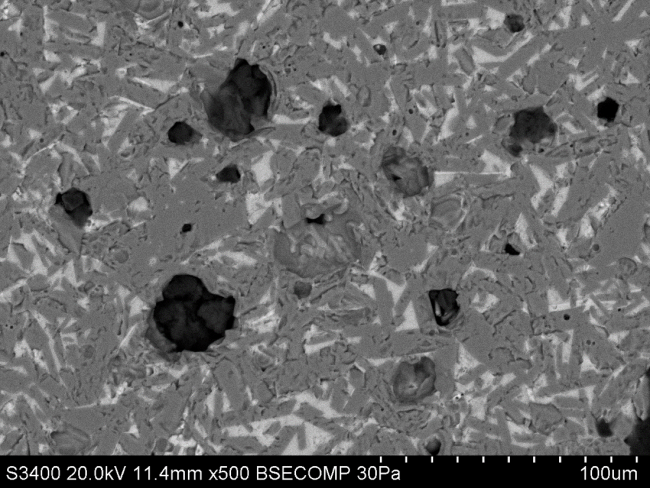

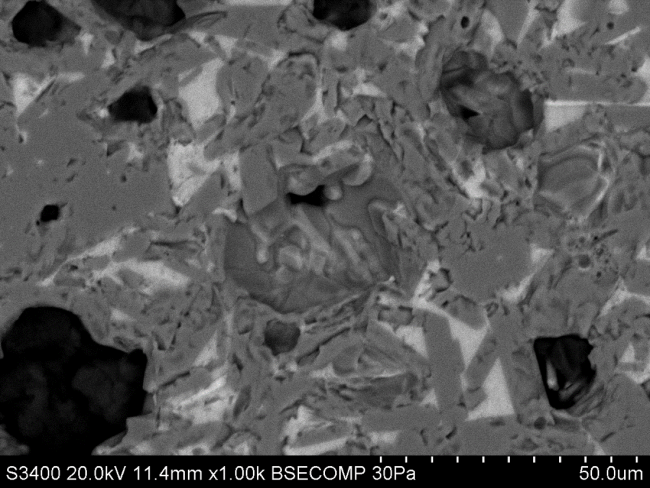

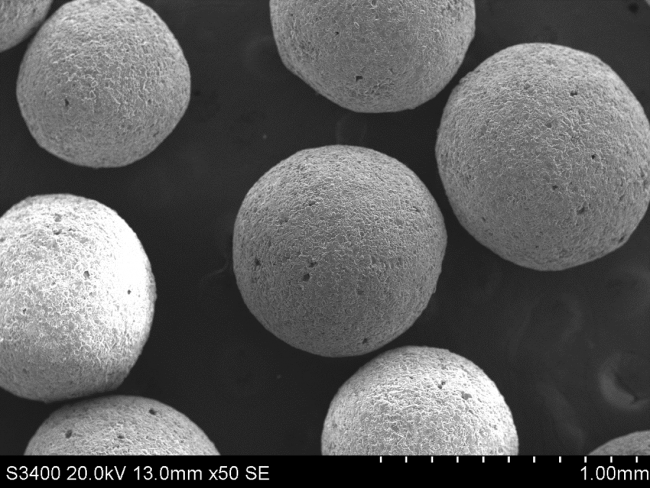

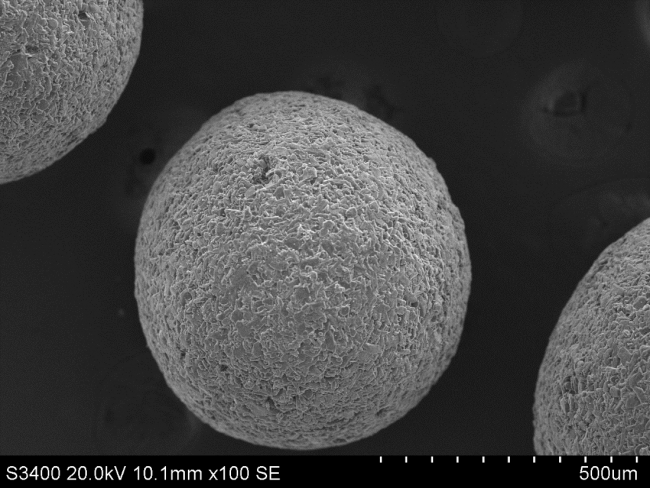

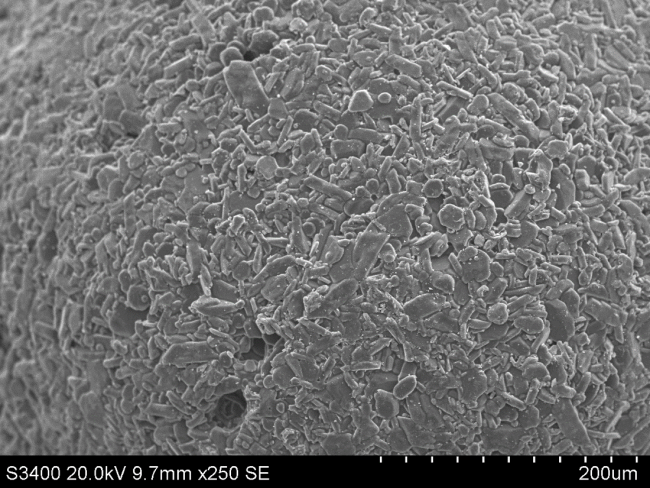

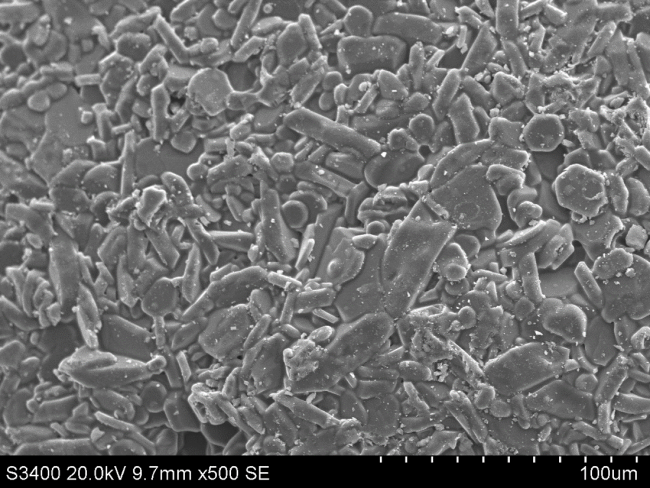

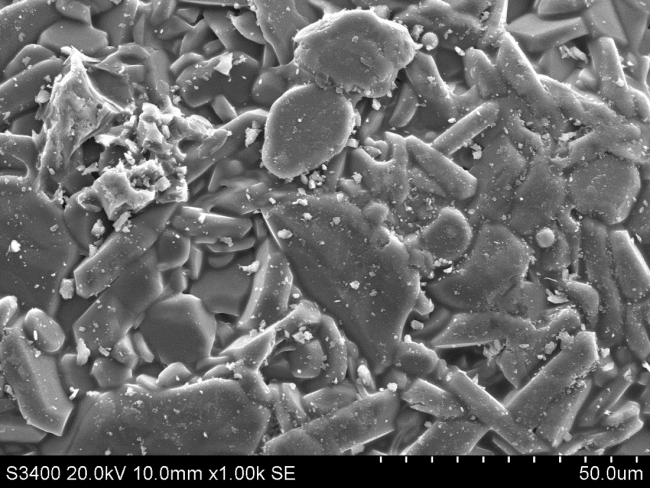

Microscopy |

|

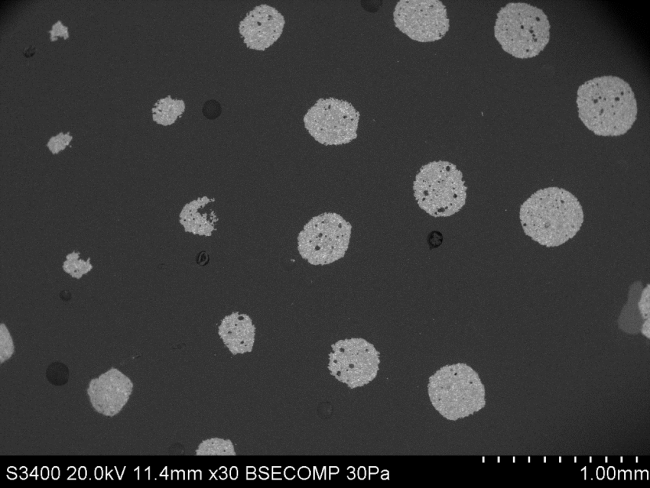

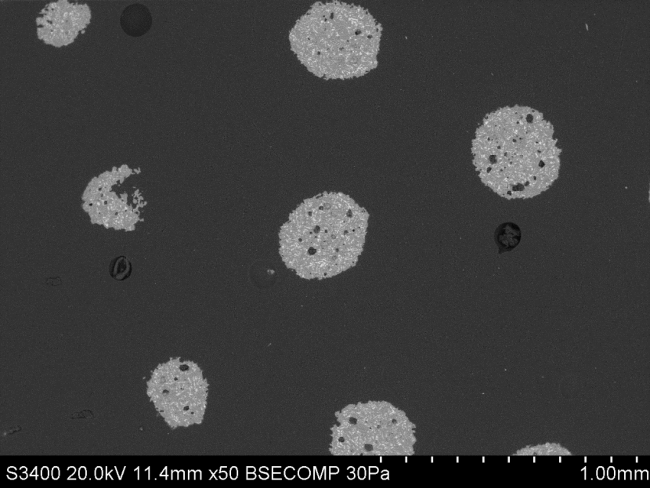

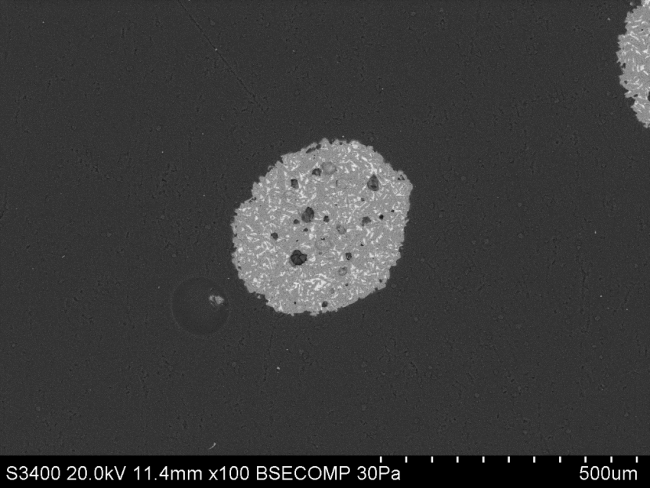

Scanning Electron Microscopy Hourly Rates |

$190.00 |

Polished Section for SEM Analysis |

$90.00 |

Optical Microscopy: Hourly Rate |

$95.00 |

Analytical Other |

|

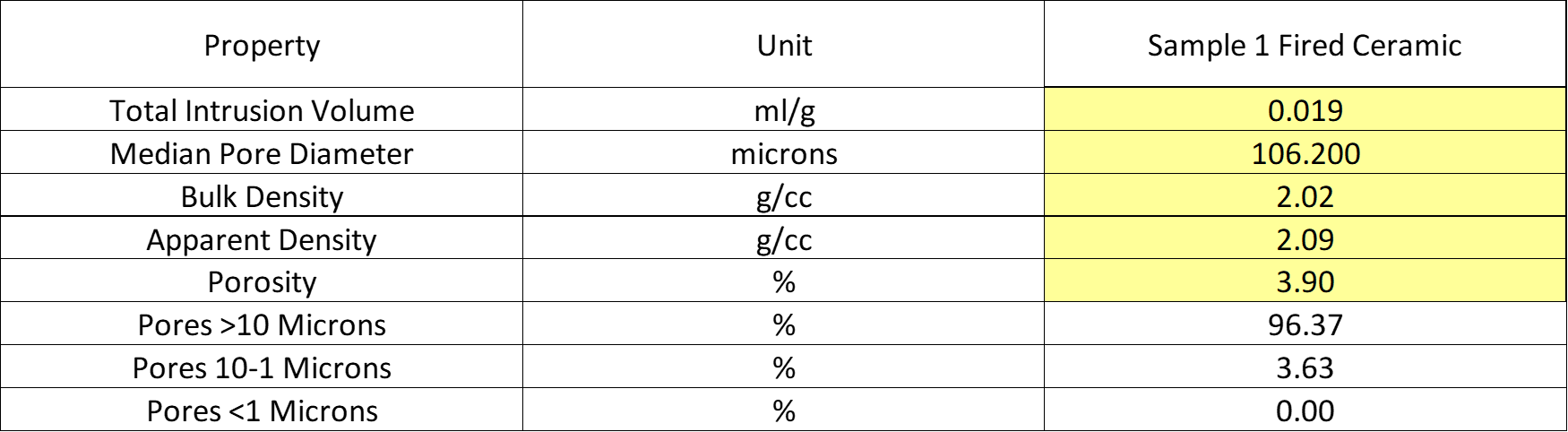

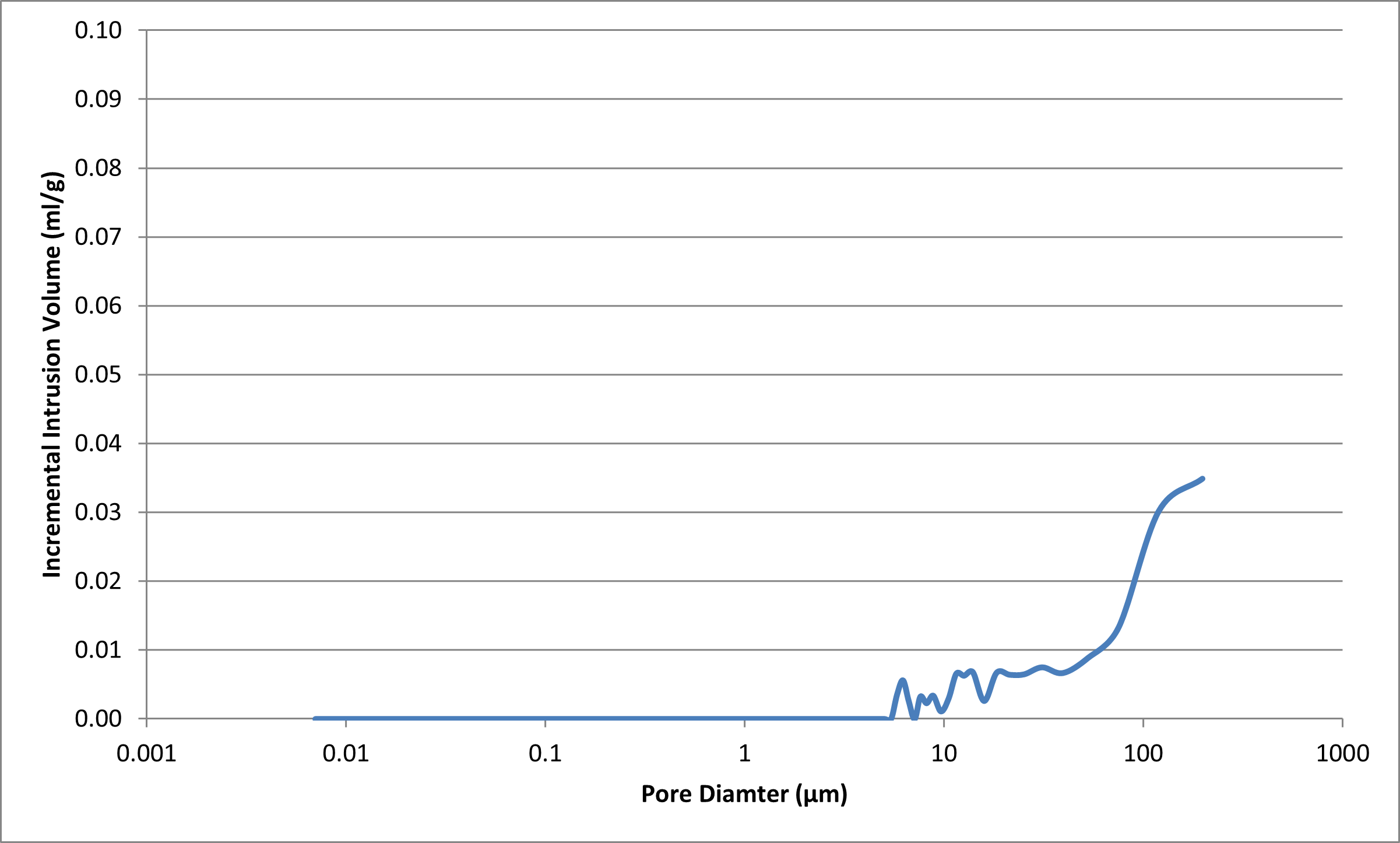

Mercury Porosimetry |

$290.00 |

Total Particle Size Analysis-by Laser Scattering |

$155.00 |

BET Surface Area Analysis |

$135.00 |

Specific Gravity by Helium Pycnometry |

$230.00 |

Powder Oil Absorption by ASTM-D281 |

$105.00 |

|

|

Sample Preparation Fee Per Individual Sample |

$30.00 |

|

|

Additional Physical and Analytical Testing Available Upon Request |

|

Standard Individual Pricing Effective February 2023. Subject to Change Without Notice. |

|

Our partnership with Clemson University’s Bishop Materials Research Center allows us to have sophisticated analyses performed, e.g., X-ray diffraction mineralogy and X-ray fluorescence chemistry.

Your Materials, Our Expertise – Let’s Elevate Quality Together

Unlock the potential of your materials through precise analysis. Whether you’re seeking to optimize product performance, troubleshoot issues, or innovate for the future, IntoCeramics’ analytical testing services have you covered. Dive into the world of accuracy and innovation – contact us today to embark on a journey of superior materials insight.

In Need of a Laser Diffraction Particle Size Analyzer?

We have top-of-the-line equipment specialized in this testing.