Frac Sand and Ceramic

Proppants: Frac Sand and Ceramic

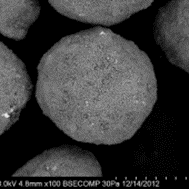

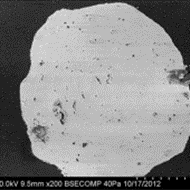

Materials used for proppants include naturally occurring sand grains called frac sand (upper left in the photo below), resin-coated frac sand (upper right), high-strength ceramic proppants (lower left), and resin-coated ceramic proppants (lower right). The size, shape, and mechanical strength of proppants influence the integrity of the newly created fractures which affects the flow of oil and gas out of the well.

Frac Sand Testing

Let IntoCeramics help you determine if you have Frac Sand or evaluate your current Frac Sand. Our Houston, TX-based Innovation Center has all the equipment and capabilities to test your sand to all API / ISO standards. We also can manage the core drilling needs of deposits.

Get In Touch

Ceramic Proppants: Full Service

IntoCeramics is the only ceramic consulting company we know of whose principals have direct experience from R&D to complete construction and start-up of a ceramic proppant manufacturing plant.

Our capabilities include:

- Proppant minerals search and procurement

- Evaluation and testing of your materials

- Formulations of all classes proppants — low, medium, high density, Ultra high density

- Kaolin and bauxite based formulations

- Unique formulations with unconventional materials

- Dry and Wet Process Capabilities for R&D and production developments

- Ceramic proppant testing API RP 19C

- Resin coating capabilities

- Plant design, equipment selection, process flows

- Capital and operating expense calculations

- Construction management

- Startup support

- Business plans and marketing

Contact IntoCeramics to learn more about our ceramic proppant consulting and expertise.